2019年7月29日 Increased demand for manganese alloys and compounds for various industries created a dire need of Manganese (Mn) ore beneficiation technology.

In view of low threshold value (10% Mn) of manganese ore revised by Indian Bureau of Mines and considering high demand for ferromanganese

2024年2月26日 In this paper, the process mineralogy of Chongqing Chengkou low-grade manganese ore will be studied in order to determine the mineral types and beneficiation methods of Chongqing Chengkou

2019年10月20日 The inferior grade of ores in mines may undergo the beneficiation process due to increasing demand in the national and international market to upgrade the quality

2016年9月12日 Significant variability in ore grades and mineralogical characteristics impose challenges during selection of a proper beneficiation process to upgrade the low-grade manganese ores.

2020年1月12日 This work reviews 24 studies on the magnetic separation of manganese ores; 6 of these studies report both a sufficiently high Mn grade (>44% Mn) and Mn/Fe

2013年8月1日 The proposed technology of processing manganese ores in a closed-cycle jet-emulsion unit allows one to significantly reduce the specific costs of materials,

2021年2月1日 In order to economically utilize low-grade manganese ores in Indonesia, a process is proposed to produce high-grade manganese concentrate and prepare calcium

2020年6月20日 Upgradation techniques like wet sieving and magnetic separation were used to evaluate the beneficiation potential of manganese ore. During wet sieving, manganese content in raw ore was...

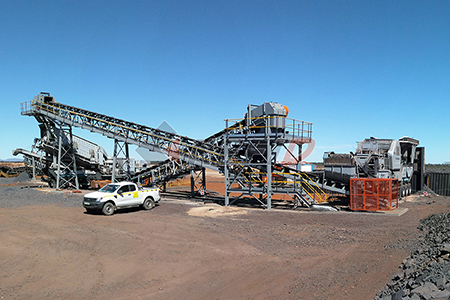

Typical Manganese Beneficiation Flow Sheet. Multotec specialises in manganese beneficiation equipment with over 50 years of global experience and leading technology. Our team of metallurgists and engineers will

2024年9月24日 Generally, it is only suitable for sorting manganese ores with simple structures and coarser particle sizes, especially manganese oxide ores with higher density. Gravity separation methods include heavy

Enhance manganese ore quality for optimal performance in alloy production. Manganese ore plays a crucial role in alloy production, particularly in the creation of ferromanganese – an alloy composed of manganese and

2021年2月1日 For low-grade manganese oxide ores, leaching manganese is preferred when other impurity minerals are insoluble. Because MnO 2 is stable in acidic and alkaline conditions, it is necessary to transform insoluble Mn (IV) into soluble Mn (II) when leaching manganese from manganese oxide ores (Sinha and Purcell 2019).Available methods

2019年3月11日 Manganese ore processing has many processes, such as magnetic separation, flotation, gravity separation and so on. In actual production Fodamon adopt, the simple and easy-to-concentrate manganese ...

2020年6月20日 Upgradation techniques like wet sieving and magnetic separation were used to evaluate the beneficiation potential of manganese ore. During wet sieving, manganese content in raw ore was upgraded ...

Siliceous manganese ore, associated with the banded iron formation occurs in large volume in northern Odisha, India. It is a sub-grade ore containing 21% Mn, 60% SiO 2 and 3% Fe, hence do not find any use and considered as waste. Such ore does not respond to any physical beneficiation techniques because of intricate microstructure and poor liberation

2021年9月23日 Commonly used manganese ore beneficiation methods are mechanical beneficiation, including ore washing, screening, gravity separation, strong magnetic separation, and flotation. Sometimes pyrometallurgy enrichment is also used. 1. ORE WASHING Ore washing is a process for treating muddy ore cemented with clay –

2015年8月3日 Increased levels of elements or minerals from ore are usually always done in the metallurgical industry. In the present investigation, low grade manganese ores from Kulonprogo, Yogyakarta has ...

2022年5月27日 The vast majority of manganese ores in China belong to lean ores, which must be beneficiated. However, most manganese ores are fine-grained, and there are a considerable number of high phosphorus ores, high iron ores, and CO (associated) beneficial metals, which brings great difficulty to beneficiation and processing.

2016年1月14日 4. Introduction:- Manganese ore in the form of ferro and silicomanganese alloys are the most essential ingredients in the production of steel, both crude and stainless. Presently, India is the second largest importer of manganese ore in the world after China. MOIL Ltd, a public sector company is the major producer of manganese ore,

2013年4月26日 Abstract: The mineralogical studies indicated that Charagah ore deposit contains approximately 17% pyrolusite, 78% calcite and 3–4% quartz. Pyrolusite as a main valuable mineral is found in the ...

2020年2月8日 Barsua iron ore mines, a captive iron ore mines of Rourkela Steel Plant, has adopted Remco Jigs for the beneficiation of low-grade iron ore fines at a size range of − 8 + 2 mm. Similarly, a Batac jig has been installed to reduce alumina content from the Noamundi iron ore fines of Tata Steel and the Apic jig used in iron ore mines of South Africa has

2011年1月1日 Manganese oxide minerals have been used for thousands of years by the ancients for pigments and to clarify glass, and today as ores of manganese metal, catalysts, and battery material.

2024年4月26日 Crushing is the initial stage in the iron ore processing journey, where large chunks of ore are broken down into smaller fragments. The primary objective of crushing is to reduce the ore size for subsequent processing and improve the liberation of valuable minerals from the gangue. a. Jaw Crushers: Jaw crushers are commonly used

2020年3月26日 2.2.1 Occurrence. Rare earth minerals occur as fluorites, oxides, tantalates, carbonates, phosphates, sulfates, borates, silicates, etc. (Qi 2018).List of different rare earth minerals are presented in Table 2.3.The average concentration of REEs in the earth’s crust is found to be 150–220 ppm, which is much higher than the concentration of

A project for the construction of a manganese ore sludge processing shop was launched. The amount of investment is estimated at $16.5 million. 2020. In 2020, the volume of emissions of harmful substances into the atmosphere by the Marganetsky GOK amounted to 230 thousand tons, of which dust – 195 thousand tons, greenhouse gases – 6 thousand ...

2013年8月1日 Most carbonate ores require washing which can be done with a shaker water spray. [41] Gravity separation is an important step in manganese ore beneficiation as it separates the ores from gangue ...

Manganese processing, preparation of the ore for use in various products. Manganese (Mn) is a hard, silvery white metal with a melting point of 1,244 °C (2,271 °F). Ordinarily too brittle to be of structural value itself, it is an essential agent in steelmaking, in which it removes impurities such

1 天前 The role of gold beneficiation reagents cannot be underestimated. More than 85% of the world’s gold ore is mainly extracted by cyanidation. However, the use of a variety of reagents mixed and added into gold beneficiation is mainly to improve the effect of flotation gold selection. Gold beneficiation reagents are important auxiliary materials in mining

حقوق الطبع والنشر: شركة خنان ليمينغ لتكنولوجيا الصناعة الثقيلة المحدودة. رخصة أعمال