Processing of taconite consists of crushing and grinding the ore to liberate iron-bearing particles, concentrating the ore by separating the particles from the waste material

The taconite is mined and then transported approximately 10 miles by rail to its processing facility in Forbes, Minnesota. Cleveland-Cliffs owns 100% of the United Taconite mine and leases 100% of the mineral rights.

2024年3月7日 A taconite iron ore processing facility separates and concentrates iron ore from taconite, a low-grade iron ore, and produces taconite pellets, which are

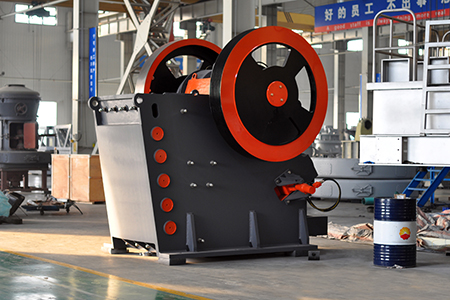

At the processing plant, the taconite is crushed into very small pieces by rock crushing machines. The crushers keep crushing the rock until it is the size of a marble. The rock is

On January 31, 2024, the U.S. Environmental Protection Agency (EPA) finalized amendments to the National Emission Standards for Hazardous Air Pollutants (NESHAP)

Taconite is a type of iron ore that is hard and low-grade, requiring processing to extract a high-grade concentrate. This process results in high volumes of tailings. From:

Every year, mining and processing of Minnesota taconite (iron ore) generates about 125 million tons of byproducts, a figure that is about double the entire state's annual construction...

2014年5月1日 The iron ore induration or pelletizing process emits particulates, sulfur dioxides (SOx), nitrogen oxides (NOx) and other pollutants depending on trace elements

2024年4月2日 Taconite is a flint-like type of rock containing low-grade iron ore. Vast reserves of taconite, with iron concentrations of 30-50%. Process. Crushing Screening;

grade ore. The six-digit source classification code (SCC) for taconite ore processing is 3-03-023. Taconite, a hard, banded, low-grade ore, is the predominant iron ore remaining in the United States. Ninety-nine percent of the crude iron ore produced in the United States is taconite. If magnetite

Contribute to dinglei2022/en development by creating an account on GitHub.

2022年10月20日 Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and washing of the ore en route to or during its various stages of treatment in the mill.. Since the physical state of iron ores in situ may range from friable, or even sandy materials, to monolithic

11.23 Taconite Ore Processing 11.23.1 General1 The taconite ore processing industry produces usable concentrations of iron-bearing material by removing nonferrous rock (gangue) from low-grade ore. The six-digit Source Classification Code (SCC) for taconite ore processing is 3-03-023. Table 11.23-1 lists the SCCs for taconite ore processing.

2016年9月9日 A taconite iron ore processing facility separates and concentrates iron ore from taconite, a low-grade iron ore, and produces taconite pellets, which are approximately 60 percent iron and about ½ inch in diameter. These pellets are then utilized, mainly, in blast furnaces making iron and steel and in the cement industry. Rule History

• EPA issued the initial air toxics standards for Taconite Iron Ore Processing on October 30, 2003. The rule applies to major source facilities engaged in separating and concentrating iron ore from taconite (a low-grade iron ore) to produce taconite pellets. These taconite pellets are then used as feed in blast furnaces to produce steel.

Taconite Ore Processing Final Report For U. S. Environmental Protection Agency Office of Air Quality Planning and Standards Emission Factor and Inventory Group EPA Contract 68-D2-0159 Work Assignment No. 4-02 MRI Project No. 4604-02 February 1997. Emission Factor Documentation for AP-42

You've already forked sbm 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

The taconite is mined and then transported approximately 10 miles by rail to its processing facility in Forbes, Minnesota. Cleveland-Cliffs owns 100% of the United Taconite mine and leases 100% of the mineral rights. Operations consist of an open-pit truck and shovel mine, where ore is crushed in two stages before traveling by rail to the plant ...

Hibbing Taconite is a Lake Superior-type granular magnetite taconite deposit occurring within the Biwabik Iron Formation along Minnesota's central Mesabi Iron Range. The deposit is situated on the northern margin of the Proterozoic Animikie Basin. The deposit strikes northeast, dips gently southeast, and occupies 10 km of strike length. Mining focuses on

Taconite Iron Ore Processing source category (40 CFR Part 63, 40 CFR part 63, subpart RRRRR). Facilities in the Taconite Iron Ore Processing source category mine and process iron ore from taconite and produce taconite pellets, which are used as feedstock to blast furnaces at integrated iron and steel manufacturing facilities.

• EPA issued the air toxics standards for Taconite Iron Ore Processing on October 30, 2003. The rule applies to major source facilities engaged in separating and concentrating iron ore from taconite (a low-grade iron ore) to produce taconite pellets. These taconite pellets are then used as feed in blast furnaces to produce steel .

2019年9月25日 As defined in the Initial List of Categories of Sources Under Section 112(c)(1) of the Clean Air Act Amendments of 1990 (see 57 FR 31576, July 16, 1992) and Documentation for Developing the Initial Source Category List, Final Report ( see EPA-450/3-91-030, July 1992), the Taconite Iron Ore Processing source category includes

The iron ore processing industry produces usable concentrations of iron-bearing material by removing nonferrous rock (gangue) from low-grade ore. In the United States, predominant iron ore is taconite which is a hard, banded, low-grade ore. Ninety-nine percent of the crude iron ore produced in the United States is taconite.

2/97 Taconite Ore Processing 11.23-1 11.23 Taconite Ore Processing 11.23.1 General1 The taconite ore processing industry produces usable concentrations of iron-bearing material by removing nonferrous rock (gangue) from low-grade ore. The six-digit Source Classification Code (SCC) for taconite ore processing is 3-03-023. Table 11.23-1 lists the ...

equipaments taconite ore processing. Taconite Crushing Equipment. Iron Ore Crushing Plant Process Crushing At the processing plant the taconite is crushed into very small pieces by rock crushing machin The crushers keep crushing the rock until it is the sie of a marble The rock is mixed with water and ground in rotating mills.

2020年8月17日 A taconite iron ore processing facility separates and concentrates iron ore from taconite, a low-grade iron ore, and produces taconite pellets, which are approximately 60 percent iron and about ½ inch in diameter. These pellets are then utilized, mainly, in blast furnaces making iron and steel and in the cement industry. Rule History

2016年5月24日 Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice.This also applies to iron ores of the non-magnetic type which after a reducing roast are amenable to magnetic separation. All such plants are large tonnage operations treating up to 50,000 tons per

2015年2月24日 The application of Vertimill® fine grinding technology at Hibbing Taconite Company enabled processing of lower grade ores and increased the concentrate production (Pforr, 2001). A sharp increase in the application of HPGR and stirred mill technologies is recorded in the last decade, driven by the benefits of increased energy efficiency and

2009年1月1日 The design outcome is a process flowsheet that specifies the required equipment and their arrangements in the beneficiation plant. The iron ore beneficiation plants normally include a series ...

حقوق الطبع والنشر: شركة خنان ليمينغ لتكنولوجيا الصناعة الثقيلة المحدودة. رخصة أعمال