2019年8月1日 Stirred media mills (also called as attritor mills) provide an overall stronger increase in mass specific surface area and are thus used for fine grinding very

2021年9月24日 The useful kinetic energy can be transferred to the powder particles of the reactant materials in these types of mills (Figure 6 a,b) via (2) collisions between the

2024年1月1日 The chapter examines the fundamental principles and operational intricacies of various milling devices used in mechanical alloying (MA), such as the conventional

2017年7月5日 The effects of major processing parameters of attritor mills on ball milling efficiency (i.e., minimum energy consumption with

2019年1月1日 There are three major types of high-energy ball mill: the shaker mill, the planetary mill, and the attritor mill. The material processing modes of the shaker mill

2017年8月24日 The most commonly used HEBMs for the production of nanocrystalline Al alloys are attritor, planetary, and Spex shaker mills. Attritor mills are known for the

2021年11月28日 Various types of ball milling methods such as vibrator mills, planetary ball mills, attritor mills, tumbler ball mills were adapted for a high throughput synthesis

2022年9月16日 The ball milling technique is a versatile top-down synthesis technique to synthesize nanomaterials, including metallic, multi-metallic, alloyed, ceramic nanocomposites, etc. It is a simple,

2017年7月5日 The effects of major processing parameters of attritor mills on ball milling efficiency (i.e., minimum energy consumption with maximum milling progress) are

2021年9月24日 Although there are various kinds of ball mills, including drum ball mills, jet ball mills, bead mills, ... Three types of nanomaterials exist: one-dimensional [1-D], two-dimensional [2-D], and three

2017年8月24日 Attritor mills are known for the production of large quantities of alloys (0.5—100 kg). Planetary mills offer a variety of options for milling volume and input energy can be varied. Some of the planetary ball mills with smaller size are capable of imparting high input energy with a speed of as much as 1000 rpm (For example Fritsch planetary P

Download scientific diagram Types of mills for high-energy milling: A-ball mill, B-planetary mill, C-vibration mill, D-attritor (stirring ball mill), E-pin mill, F-rolling mill. 4k Modified from ...

Ball Milling Method for Synthesis of Nanomaterials W. Cao . Skyspring Nanomaterials, Inc. ... The alloying process can be carried out using different apparatus, namely, attritor, planetary mill or a horizontal ball mill. ... Small experimental ball mills can also be completely enclosed in an inert gas glove box.

Versatility: Attritor mills can be used for a wide range of materials, including those that are difficult to grind using other methods. FAQs about Attritor Mills What types of materials can be ground using an attritor mill? Attritor mills can be used for a wide range of materials, including metals, ceramics, pigments, and chemicals.

The typical mill used for these purposes has been the high energy ball mill such as tumbler ball mills, vibratory mills, planetary mills, and attritor mills (Szegvari attritor) etc. A detailed description of the different mills available for MM can be found in Suryanarayana handbook [25]; however we have discussed a brief description regarding high energy ball

2012年2月3日 such as tumbler ball mills, vibratory mills, planetary mills, and attritor mills (Szegvari attritor) etc. A detailed descrip-tion of the different mills available for MM can be found in Suryanarayana handbook [25]; however we have discussed a brief description regarding high energy ball mills. Figure 1. A rock tumbler Ball mills

Request PDF On Sep 1, 2013, Priya R. Santhanam and others published Discrete element model for an attritor mill with impeller responding to interactions with milling balls Find, read and cite ...

Attrition Mills from Munson Machinery are ideally suited for reducing fibrous and friable materials within a relatively narrow particle size range from coarse down to 100 mesh. Typical applications include materials that cannot be reduced by impact (hammer mills or pin mills) or by screen classification ...

Planetary mills: As a subcategory of ball mills, planetary mills are used primarily for reducing sample material in laboratories, though they are also used for mechanical alloying. Rotormills : Also referred to as “long gap mills” due to the lengthy annular gap between its inlet and discharge, rotormills are used to manufacture abrasive products and for less

Buying and Selling Unused, Used and Reconditioned Attritor Mills. Phoenix Equipment is a global buyer and seller of unused, used and reconditioned Attritor Mills from industry leaders like Union Process, Robinson,

The typical mill used for these purposes has been the high energy ball mill such as tumbler ball mills, vibratory mills, planetary mills, and attritor mills (Szegvari attritor) etc. A detailed description of the different mills

The ball mills mainly include shaker mills, attritor mills and planetary ball mills. For the preparation of alloy fuels, planetary ball mill is the most appropriate. The main processing parameters include ball to powder weight ratio ... Muthupandian Ashokkumar, in Nanomaterials for Green Energy, 2018.

Used Union Process Batch Attritor Mill Model 15S, Union Process Batch Attritor Model 15S, Variety Steel Fabricators Pressure Vessel, Serial No: 5776, Pressure on Jacket: 100 PSI @ 350 F, 5HP Reliance Motor to turn agitator: 575 Volt, 1695 RPM, Frame: 284T, Includes 2HP Diaphragm Pump, Demonstration video available.

Realspa è con voi per sviluppare soluzioni personalizzate per l'installazione degli impianti ATTRITOR MILL. Ogni progetto è ottimizzato per massimizzare l'efficienza operativa e garantire un flusso di produzione fluido e performante.

AttritorTrade è leader nella gestione sostenibile dei rifiuti grazie alla tecnologia all’avanguardia del Attritor Mill™.. La nostra missione è rivoluzionare il trattamento dei rifiuti convertendo i rifiuti solidi in prezioso combustibile CSS e riducendo i tempi di stabilizzazione dei rifiuti organici.

Get Attritor Mill Machine in Bhosari, Pune, Maharashtra at best price by Vimson India Engineers. Also find Attrition Mills price list from verified suppliers with contact number ID: 4295379688. IndiaMART. All India. Get Best Price. Shopping. Sell. Help. Messages. Sign In.

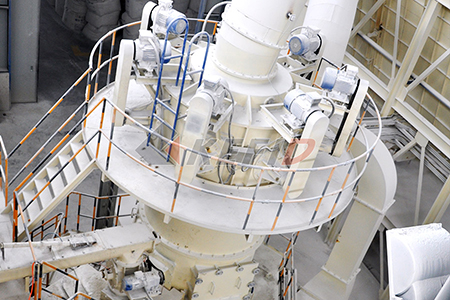

2021年9月24日 (a) A Photo of an attritor ball mill; sketches illustrate (b) ball movement inside attritor ball mill, (c) impact, and (d) shear forces generated by the ball milling media. The equipment is housed in the Nanotechnology and Applications Program (NAP), Energy and Building Research Center (EBRC), Kuwait Institute for Scientific Research (KISR).

Applications of Attritor Type Ball Mills: 1. Chemical Industry: Attritor mills are widely used in the chemical industry for the grinding and mixing of various chemicals, including pharmaceuticals, pesticides, and fine chemicals. They are also used for the production of catalysts and other intermediate products. 2.

Atritor mills can take materials of up to 98% moisture and dry and mill them simultaneously. Designing a drying process requires recognition of the characteristics of a material, in particular, how it may be adversely affected by heat. Fine Milling.

حقوق الطبع والنشر: شركة خنان ليمينغ لتكنولوجيا الصناعة الثقيلة المحدودة. رخصة أعمال